Amidst the torrid sun in Southeast Asia, adjacent to the deserts of the Middle East, within the burgeoning cities of Africa, and on the vast plateaus of Central Asia, construction projects are booming. For construction companies in these regions, identifying a trustworthy scaffolding enterprise to collaborate with is pivotal for the seamless progression of their projects.

Selecting the Appropriate Scaffolding Enterprise: Grasping the Project’s Lifeline

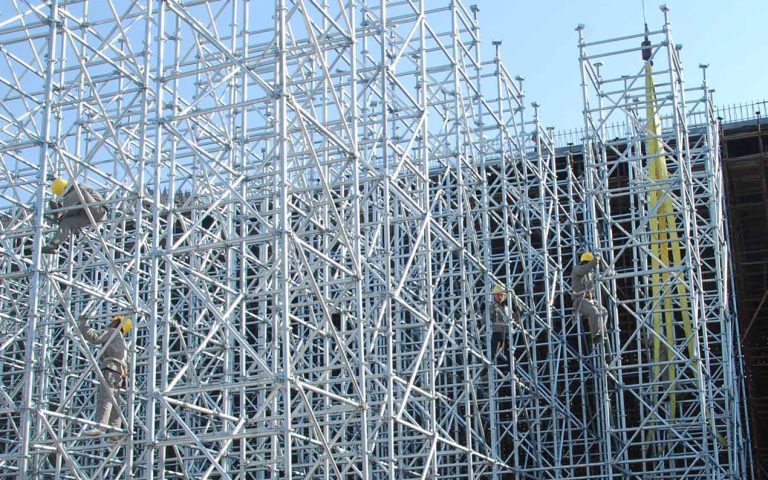

Construction in these areas is confronted with diverse climatic conditions, varying construction terrains, and substantial cost constraints. Thus, when construction enterprises are in the process of choosing scaffolding suppliers, their primary concerns revolve around the adaptability of products to complex environments, cost – effectiveness, and punctual delivery. High – grade scaffolding can maintain its structural integrity during the monsoon seasons in Southeast Asia, the sweltering heat in the Middle East, the sand – laden storms in Africa, and the frigid winters in Central Asia, safeguarding construction safety. Reasonable pricing and timely supply can effectively manage project budgets and timelines.

Keeping a Keen Eye to Discern High – Quality Scaffolding Enterprises

So, how can one single out top – notch scaffolding enterprises? There are several crucial aspects. Firstly, the enterprise’s R & D and innovation capabilities should be scrutinized, as they determine whether its products can meet the evolving construction demands. Secondly, its supply chain management prowess must be evaluated to ensure seamless order fulfillment. Thirdly, the local service proficiency in target regions like Southeast Asia, the Middle East, Africa, and Central Asia is vital, as a local service team can expeditiously address any issues. Moreover, the enterprise’s certification credentials, past project portfolios, and market reputation serve as significant benchmarks for assessing its reliability.

Chinese Scaffolding Enterprises: The Ascendant New Force in the Industry

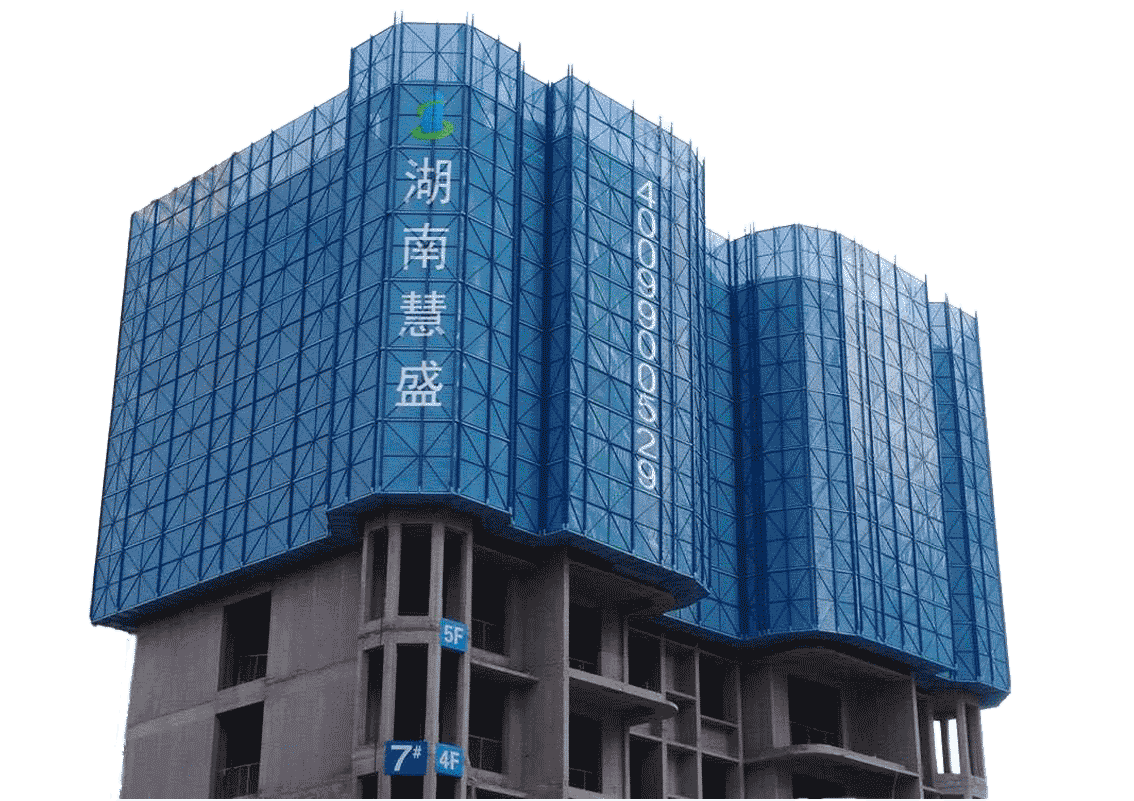

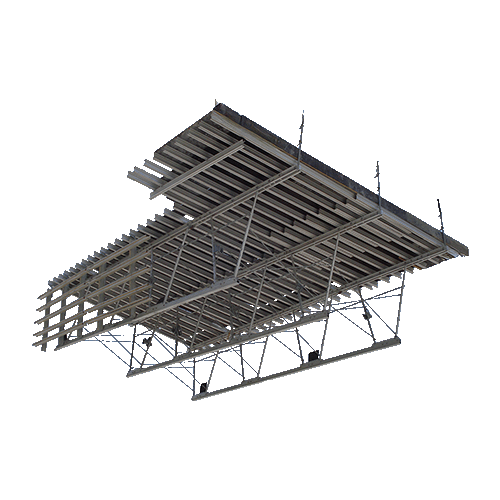

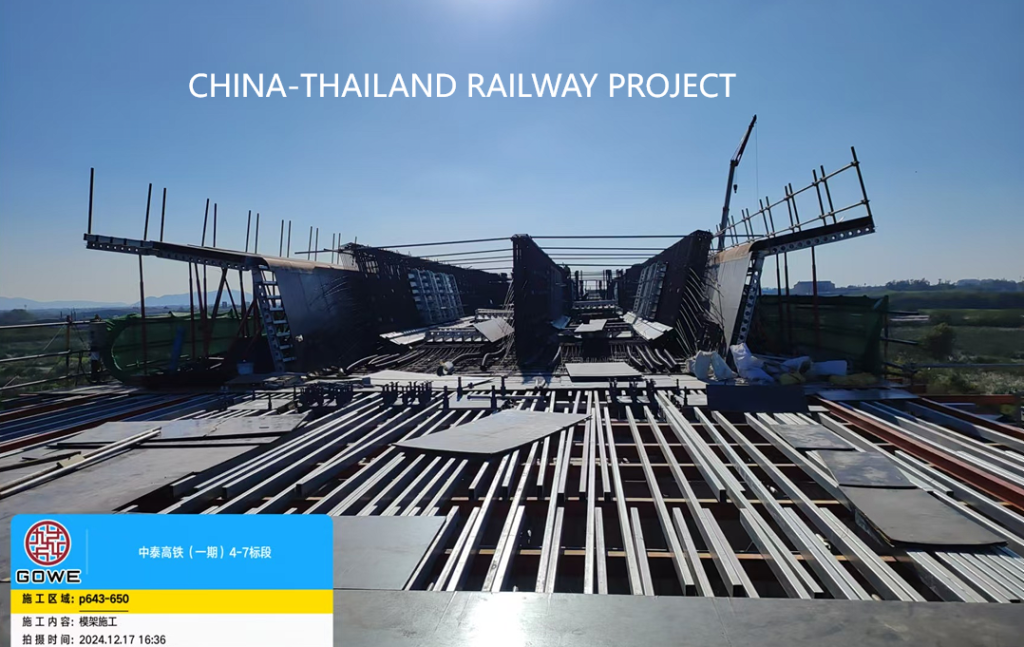

In recent years, Chinese scaffolding enterprises have been making remarkable strides on the global stage. Prominent players such as Hongxin Jianfa, Gowe Group, and GETO have emerged as formidable competitors to international heavyweights like Doka and PERI in multiple dimensions. Take Gowe Group, for instance. Its integrated formwork – scaffolding system solution has proven to be highly effective in large – scale construction projects across Southeast Asia, the Middle East, and other regions. Gowe Group offers an extensive product lineup, including Scaffolding, Aluminum formwork, Steel formwork, Timber formwork, Steel – structure products, steel tube & couplers and more. Additionally, it provides a comprehensive suite of services, including building formwork & scaffolding consultation, design, and construction.

In terms of production capacity, Gowe Group stands at the forefront of the industry. Boasting nearly 20 factories and warehousing facilities both domestically and overseas, it can promptly respond to orders from all corners of the globe. Equipped with the first Research Institute in this field of China, Gowe Group is constantly driving technological innovation, giving it a distinct edge. That’s why even during the period from 2021 to 2024, when the construction industry faced a downturn, Gowe Group, buoyed by its cost – competitive products, efficient operations, and robust R & D and quality – control mechanisms, achieved an annual growth rate of over 20% annually. Its overseas market expansion has been particularly impressive. Currently, Gowe Group has established branches in Singapore, Malaysia, Thailand, Saudi Arabia, and is actively venturing into Eastern Europe, Central Asia, and Central and South America.

For construction enterprises in Southeast Asia, the Middle East, Africa, and Central Asia, partnering with a high – caliber Chinese scaffolding enterprise like Gowe Group not only ensures access to reliable products and services but also empowers them to execute construction projects smoothly in complex environments, cut costs, and enhance overall efficiency.