Choosing the right formwork and scaffolding is key to keeping your construction project safe, efficient, and on schedule. With so many options on the market, picking the best system can feel overwhelming. Here’s a practical guide to help you make the right choice.

1. Understand Your Project Needs

Start with the basics:

- Project size and complexity: Larger, more complex projects usually need modular, flexible systems.

- Concrete structure type: Walls, slabs, columns, and beams often need different formwork.

- Timeline: Some formwork systems are faster to install and dismantle than others.

- Budget: Material choices—like steel, aluminium, or timber—can significantly affect cost.

Before looking at brands or suppliers, list your project’s specific formwork and scaffolding needs.

2. Choose the Right Formwork Material

The material you choose directly impacts cost, durability, and surface finish. Here’s a quick breakdown:

- Timber Formwork: Cheap, easy to customize, but not very durable. Best for small, simple projects.

- Plywood Formwork: Smoother finishes than plain timber, often used for slabs and beams.

- Steel Formwork: Durable, reusable, ideal for large projects. It’s more expensive but pays off over time.

- Aluminum Formwork: Lighter than steel, fast to erect, and good for projects with repetitive designs.

- Plastic Formwork: Lightweight, reusable, and water-resistant—suitable for more minor, modular works.

Tip: If your project demands a high-quality finish, steel or aluminium might be worth the extra cost.

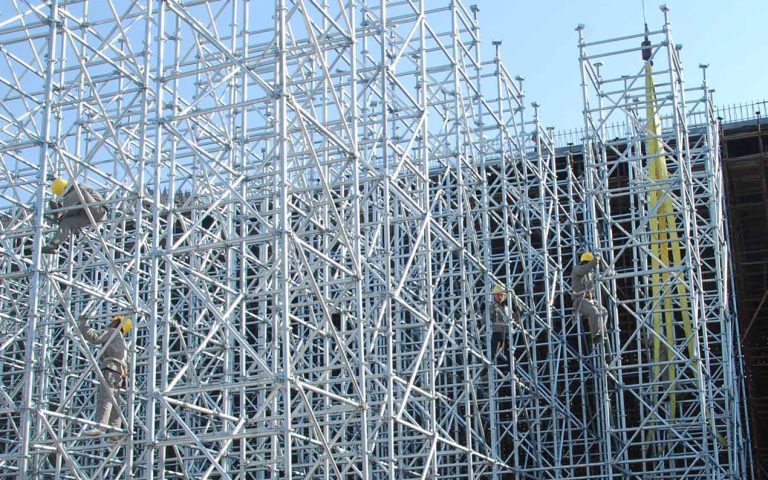

3. Pick the Right Scaffolding System

Scaffolding provides temporary support and safe access for workers. Choose based on:

- Height and load capacity: Heavier loads and higher elevations need stronger scaffolding.

- Type of work: Painting, masonry, formwork setting—each task needs a different setup.

- Worksite conditions: Rough terrain might call for adjustable or mobile scaffolding.

Common types include:

- Tube and Coupler Scaffolding: Flexible but labour-intensive to assemble.

- System Scaffolding (like Cuplock, Ringlock): Pre-engineered for faster, safer builds.

- Suspended Scaffolding: Great for high-rise maintenance and lighter loads.

Always prioritize systems with solid safety ratings and compliance certifications.

4. Factor in Labor and Skill Level

Even the best formwork and scaffolding can cause problems if your team isn’t trained. Complex systems like custom steel formwork or modular scaffolding may need skilled labour.

If you’re working with a less experienced crew, choose simpler, easy-to-assemble systems to avoid delays and mistakes.

5. Check Rental vs. Purchase Options

Buying equipment makes sense for long-term or multiple projects. Renting is often smarter for one-off jobs.

When renting, ensure the equipment is inspected, certified, and in good condition.

When buying, look for warranties, support services, and the ability to resell or reuse for future projects.

6. Choose a Trusted Supplier

Working with an experienced, reliable supplier can save you time, money, and stress.

Gowe is a one-stop solution for all your formwork and scaffolding needs.

They offer a full range of systems designed for safety, efficiency, and durability, supporting projects of every size and type. Whether you need custom formwork, modular scaffolding, or on-site support, Gowe has the expertise to help you deliver your project successfully.

7. Don’t Skip Safety and Compliance

Every country and region has strict regulations about scaffolding and formwork. Make sure whatever you choose meets local safety codes.

Regular inspections, correct assembly, and load testing aren’t optional—they’re essential.

Final Thoughts

Choosing the right formwork and scaffolding isn’t just about saving money. It’s about keeping your people safe and your project moving.

Know your project, choose the right materials, match the system to your crew’s skill level, and work with trusted experts like Gowe.

A wise choice upfront saves you headaches later.